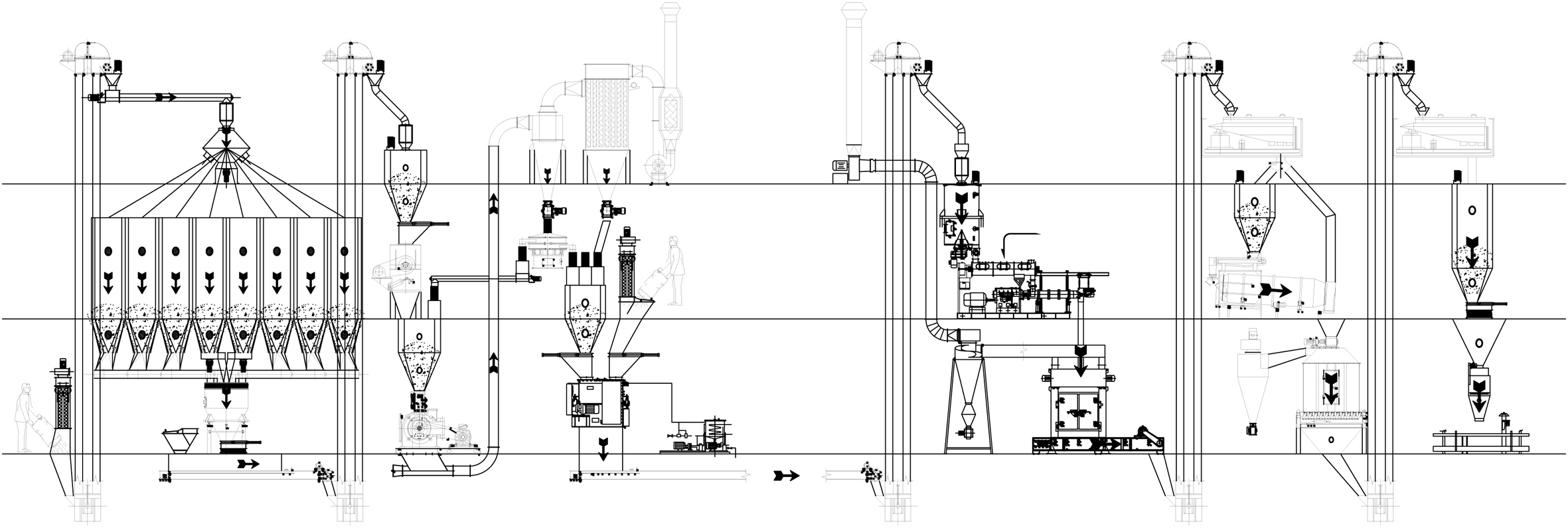

Large Aquatic Feed / Pet Food Production Line

Main Features:

Large-scale production line can produce a premium quality special koi food, goldfish food, tropical fishes food, dog food, cat food, as well as dog and monkey food. They all are sold at home and abroad and win high praise and favorably commented from customers. This production line adopts steam method with high efficiency driving, stable and low noise.It is with International advance steam fittings and imported pressure reduction valve.

Production Line Introduction:

The fully automatic pet food production line is developed and continuously improved by our company based on the ever-developing pet food market and our years of experience in pet food machinery research and development. This production line can use animal bones, fresh meat, fish and shrimp, animal offal, as well as flour, corn flour, soybean meal, meat powder, fish powder, bone powder, etc. as raw materials.

The production line gives pet food novel shapes, unique flavors, and colors, and adapts to the needs of the modern pet food market with scientific nutritional ratios and easy-to-digest characteristics. The automatic mixing system achieves fully automatic scientific proportion mixing, the twin-screw extruder extrudes various shapes, and then drying and spraying can produce various shapes, nutritionally balanced, palatable formula pet foods.

Pet Food Shapes:

Heart shape, bone shape, round shape, triangular shape, fish shape, square shape, etc.

I. Production Line Introduction:

Raw Material Handling System → Extrusion System → Vibrating Screen → Air Conveying Machine/Elevator → Multi-layer Oven → Elevator → Seasoning System → Cooling Conveyor → Packaging Machine

II. Process Composition:

A complete pet food production line usually includes a raw material handling system, pet food forming system, drying system, seasoning system, and packaging system.

1. Raw Material Handling System: A large-scale pet food production line generally has an integrated raw material handling system. The integrated raw material handling system can integrate the crushing system, automatic weighing and proportioning system, etc., which not only makes the proportioning more accurate but also greatly improves production efficiency and reduces labor requirements.

2. The pet food forming system mainly uses extrusion technology based on the type of pet food produced. There are also a few cold pressing machines that use cold pressing technology, etc. This series of production lines uses an extrusion system, and our extrusion system has a wide range of applicable raw materials, high production efficiency, and the extrusion system developed for large-scale production lines can reach a maximum output of over 10 tons (usually the output is less than 3 tons).

3. For small-scale pet food production lines, the usual configuration of the drying system is an electric oven. Because compared to fuel and gas ovens and steam ovens, electric ovens are more convenient. However, for large-scale pet food production lines, the capacity of electric ovens is difficult to meet production needs, and in such cases, according to customer needs, customers are configured with fuel and gas or steam ovens.

4. The seasoning system can spray oil on pet food and add seasonings, etc. Common configurations include drum seasoning machines and vacuum spraying machines.

5. The packaging system can also be configured with various packaging machines according to actual production and sales needs.

III. Equipment Features:

1. Highly integrated and automated, precise配料, fine control, high production efficiency.

2. Automatic lubrication system, reducing mechanical energy consumption and prolonging service life.

3. The main machine has an automatic cleaning function, no need to disassemble the screw for cleaning when stopping.

4. All machines on the entire production line, the parts in contact with the material, are made of food-grade stainless steel and other food-grade materials.

5. Hot air circulation oven with dehumidification function, improving drying efficiency.

6. Highly customization. According to the characteristics of the customer’s factory, a scientifically reasonable plan is designed to maximize the use of factory space and configure the most reasonable machines.

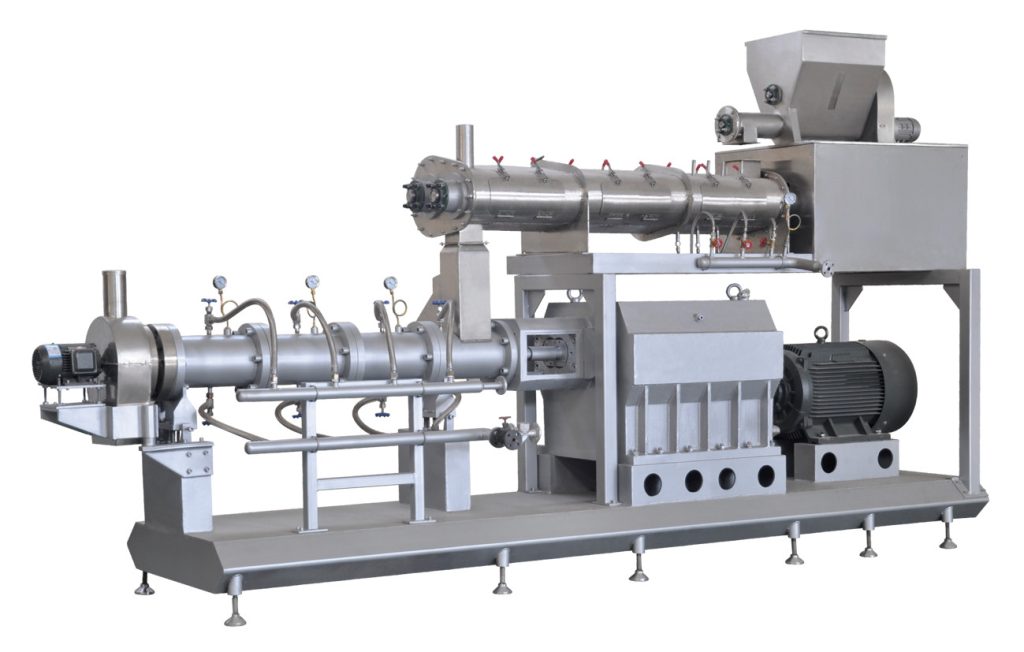

Twin-screw Extruder

The Twin-screw extruder is made up of the feeding system, extruding system, cutting system, heating system, transmission system and controlling system. We will feed the material from the feeding machine and get the tissue state by inflating the material and the machine barrel must be high temperature, high pressure and high cutting. The material can be sterilized by the high temperature and high pressure and make the product safe.

The main extruder adopts frequency speed controlling with high automation and stable per-formation.

●The screws are made of the alloy steel and special craft, durable usage, high pressure, the screw life is longer. Adopting the building block structure and combining willingly according to the different demand.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

●Self-cleaning, when stopping, it can be cleaned without disassembling.

●According to different screw design rate to full different technology request.

This equipment has the wide material, multi-shape products and flexible collocations. We can produce the different products ac- cording to the different models and collocations.

Dryer

The dryer can be used to bake all kinds of puffed food, pet-food, tissue protein and various nuts including peanuts, melon seeds and dried jujube.

Dryer is compact, has small dry area and a large superficial area. It also features small scale of heat elimination and high thermal efficiency.

Mesh belt conveyors and thermal insulation boards all use stain- less steel material, making the equipment clean and sanitary. The speed of mesh belt conveyor is adjustable. The drying period for food in the oven can be adjusted.

The automatic temperature control system makes it possible to set the temperature according to your needs.