Qingdao Cina Industry and Trade Co., Ltd.

Qingdao Cina Industrial & Trade Co., Ltd. was established in 2014, and at the time of its establishment, our company’s main business was the design and construction of industrial and agricultural buildings, as well as the installation of industrial, agricultural, and fishery production lines and electromechanical equipment. Due to the company’s demand for transformation and development, it began to engage in international trade in 2023. Currently, the company’s main businesses targeting the international market include: the sale of various mechanical equipment for agriculture, forestry, husbandry, fishery and aquaculture; the design, sale and construction of land-based aquaculture workshop; the design, sale and construction of various greenhouses; consulting, designing and constructing of fish-solar power generation projects; the production, design, sale and construction of recirculating water aquaculture systems; consulting, training and construction of fish-vegetable symbiosis and soil-free cultivation systems; the production, sale and installation of feed production lines; the sale of various feed additives; the design of small rooftop photovoltaic power stations and the sale of energy storage products; and the provision of technical services, technical development, technical consulting, technical exchange, technology transfer, and technology promotion in related industries.

Recirculating Aquaculture Systems (RAS)

Recirculating Aquaculture System (RAS) is a new type of farming model in which waste water produced in aquaculture ponds is treated and recycled through a series of water treatment units. This system can solve the problem of low water utilization, and provide a stable and high-quality living environment for aquaculture organisms, especially for high-density farming.

The main components of the RAS system include:

Aquatic hatching system

Aquaponics is a technology that combines aquaculture and hydroponics to achieve synergistic symbiosis through ecological design. In this system, fish waste is converted into nutrients that can be absorbed by plants, while plant growth helps to purify water and form a sustainable, circular, zero-emission, low-carbon production model. The aquaponics system can be divided into various cultivation modes according to specific cultivation methods, including substrate culture, deep-water floating raft culture, nutrient film pipeline culture and aerosol culture.

Fish-light complementarity

Fish-light complementarity means that a photovoltaic panel array is set up above the water surface of the fish pond, and the waters below the photovoltaic panel can be cultured for fish and shrimp, and the photovoltaic array can also provide a good shelter for fish farming, forming a new power generation model of “upper power generation and lower fish farming”. This model can not only save land resources, but also improve the economic value of the unit area.

Feed production line and

feed additives

Large-scale production line can produce a premium quality special koi food, goldfish food, tropical fishes food, dog food, cat food, as well as dog and monkey food. They all are sold at home and abroad and win high praise and favorably commented from customers. This production line adopts steam method with high efficiency driving, stable and low noise.It is with International advance steam fittings and imported pressure reduction valve.

-scaled.jpg)

Aquaponics (soilless culture)

Aquaponics is a technology that combines aquaculture and hydroponics to achieve synergistic symbiosis through ecological design. In this system, fish waste is converted into nutrients that can be absorbed by plants, while plant growth helps to purify water and form a sustainable, circular, zero-emission, low-carbon production model. The aquaponics system can be divided into various cultivation modes according to specific cultivation methods, including substrate culture, deep-water floating raft culture, nutrient film pipeline culture and aerosol culture.

Aquaculture plant workshop design and construction

(Greenhouse and steel structure workshop)

When designing and constructing fish and shrimp hatcheries and farms, it is necessary to consider various aspects to ensure efficiency, safety, and environmental sustainability. Here are some points to keep in mind based on our years of design and construction experience:

1. Design specifications and environmental requirements

• Compliance with construction specifications: Design and construct according to the “Specifications for Construction of Fish Farming Facilities” to ensure compliance with customer country’s agricultural industry standards.

• Water quality management: Comply with the “Standard for Fish Water Quality” to prevent and control water pollution in fishery waters and ensure normal growth and reproduction of fish and shrimp.

• Compliance with environmental regulations: Comply with environmental regulations during construction and properly handle construction waste and wastewater.

2. Construction supervision and material procurement

• Pre-construction preparations: Review design drawings, construction contracts, etc. to ensure compliance with regulations and standards, and conduct on-site inspections.

• Construction site supervision: Closely monitor construction progress and quality to ensure that safety measures are implemented, and communicate and coordinate with the construction unit.

• Material procurement: Our company is a regular supplier, ensuring reliable material quality that meets relevant standards, and recording the quantity and quality of construction materials.

3. Workshop design and construction

• Isolation and disinfection: Hatcheries should pay special attention to the isolation of dirty areas from clean areas, setting up isolation belts and disinfection pools.

• Ventilation design: Rationally design ventilation systems and recirculating aquaculture systems(RAS) to ensure hatching rates, and discharge exhaust gases and wastewater outdoors and supplement with fresh air and water.

• Lighting system: Provide suitable light cycles and intensities to simulate natural light conditions to optimize hatchery productivity.

• Biosecurity measures: Implement robust biosecurity measures, including strict hygiene protocols, controlled entry points, and regular health monitoring.

4. Functional area layout

• Production area layout: Fish and shrimp farming workshops and nursery workshops should be concentrically arranged or arranged in rows to consider usage functions and site conditions.

• Technical Area: The technical area should be divided into individual rooms for electrical installation, hot water installation, and ventilation, to reduce the number of times engineers enter the hatchery.

• Personnel Facilities: Provide sufficient air showers and changing rooms, as well as separate canteens for personnel who handle the transportation of parents and parents, and the handling of eggs and larvae and juveniles.

General Services

Sales of agricultural, forestry, animal husbandry, fishery machinery and equipment;

Design, sales and construction of land-based factory fish culture workshop;

Design of small rooftop photovoltaic power stations and sales of energy storage products;

Consulting, design and construction of fishing and light complementary projects;

Production, design, sales and construction of recirculating aquaculture systems;

Consulting, training and construction of aquaponics and soilless culture systems;

Production, sales and installation of feed production line;

Sales of various feed additives;

Design, sales and construction of various greenhouses;

Provide technical services, technical development, technical consultation, technical exchange, technology transfer, technology promotion, etc., in the above related industries.

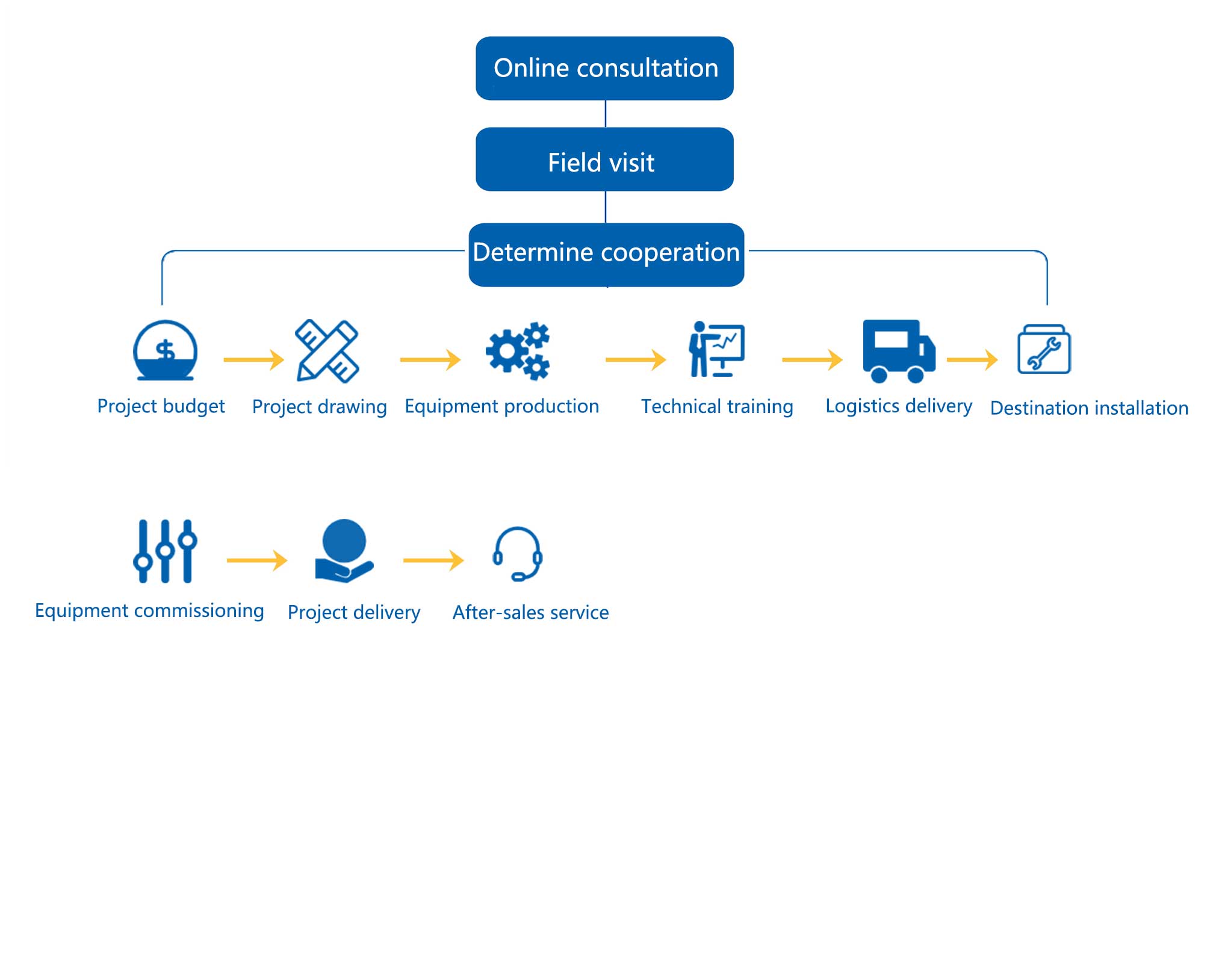

Service Process